Putting you in control

Working closely with UK and Australian growers, we have been developing commercial robotic harvesting solutions since 2016. Our fifth generation robots are available to buy now.

“Dogtooth robots will form an integral part of our harvesting team, augmenting our valued seasonal workforce – working through day and night to bring the freshest fruit to our customers”

Marion Regan

Managing Director at Hugh Lowe Farms

We are delivering commercially at scale

Our robots have been harvesting commercially on 10 customer sites over 10 seasons

We are manufacturing 100s of robots per year

We support standard tabletop infrastructure in glasshouse and polytunnel

Scaling with harvest peak through night picking & multiple shifts

A rich innovation pipeline, including yield monitoring & forecasting and raspberry & apple picking

We are already working with customers across the globe

Putting growers at the heart of their business

Yield insight from robot data

As they travel along each crop row, Dogtooth’s robots count berries at each stage of maturity, providing insights into yield

Quality insight from on-board inspection

Dogtooth’s patented inspection system uses 360 degree imaging of every picked berry to determine mass and ripeness and identify a wide range of defects

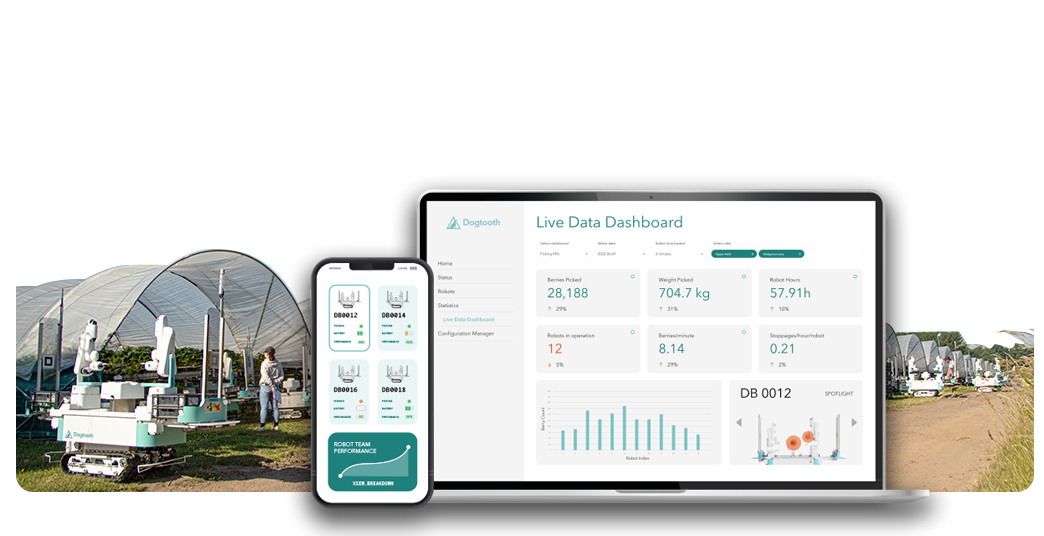

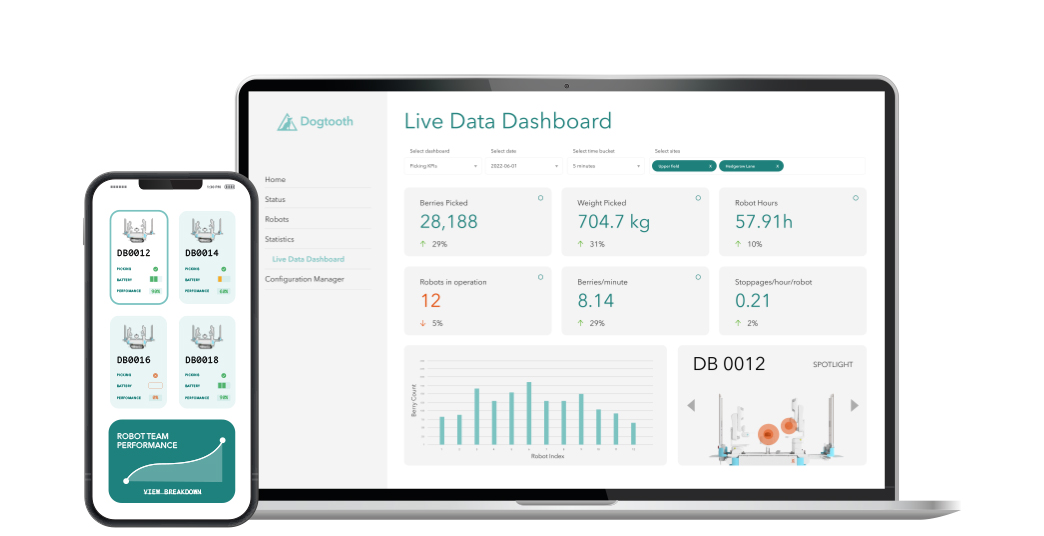

Web portal allows complete control of your robot fleet

Gain real-time insight into crop conditions including yield and defect rates. Remotely adjust ripeness and grading settings and the trade-offs between wastage, extraction rate and picking speed

Interested in robotic harvesting on your farm?