Strawberry Harvesting Robots

Putting Growers at the Heart of Their Business

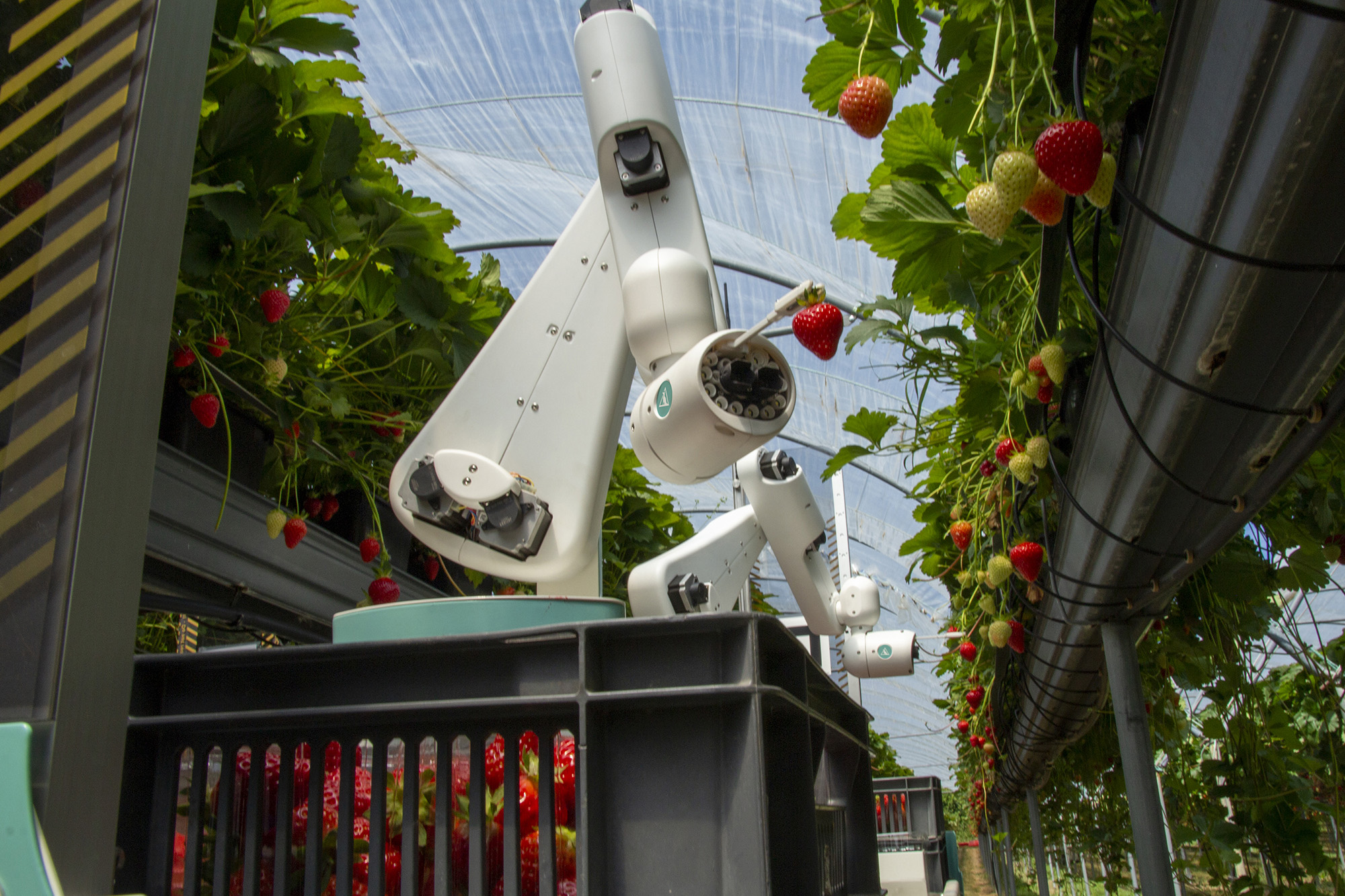

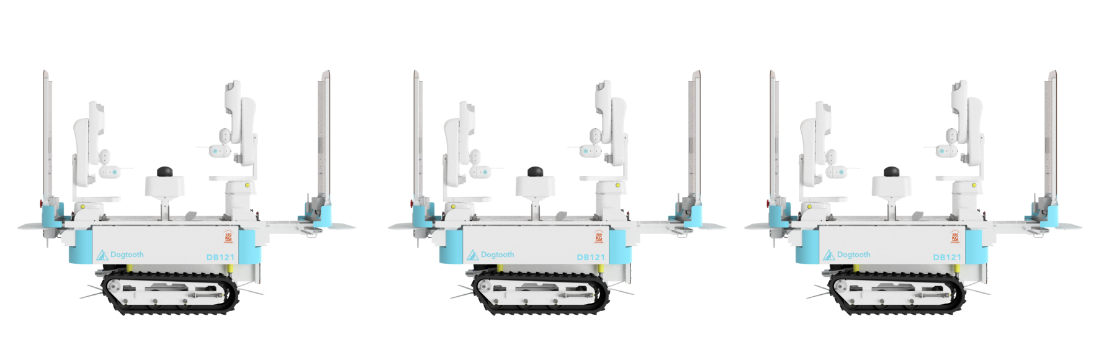

Fifth generation robots pick 200kg per day

Our strawberry harvesting robots work with the table-top growing systems widely used around the world – in both glasshouse and polytunnel environments. They are capable of autonomous navigation along crop rows, locating and picking ripe fruit, and on-board quality control – grading picked berries, and placing them directly into punnets according to supermarket criteria.

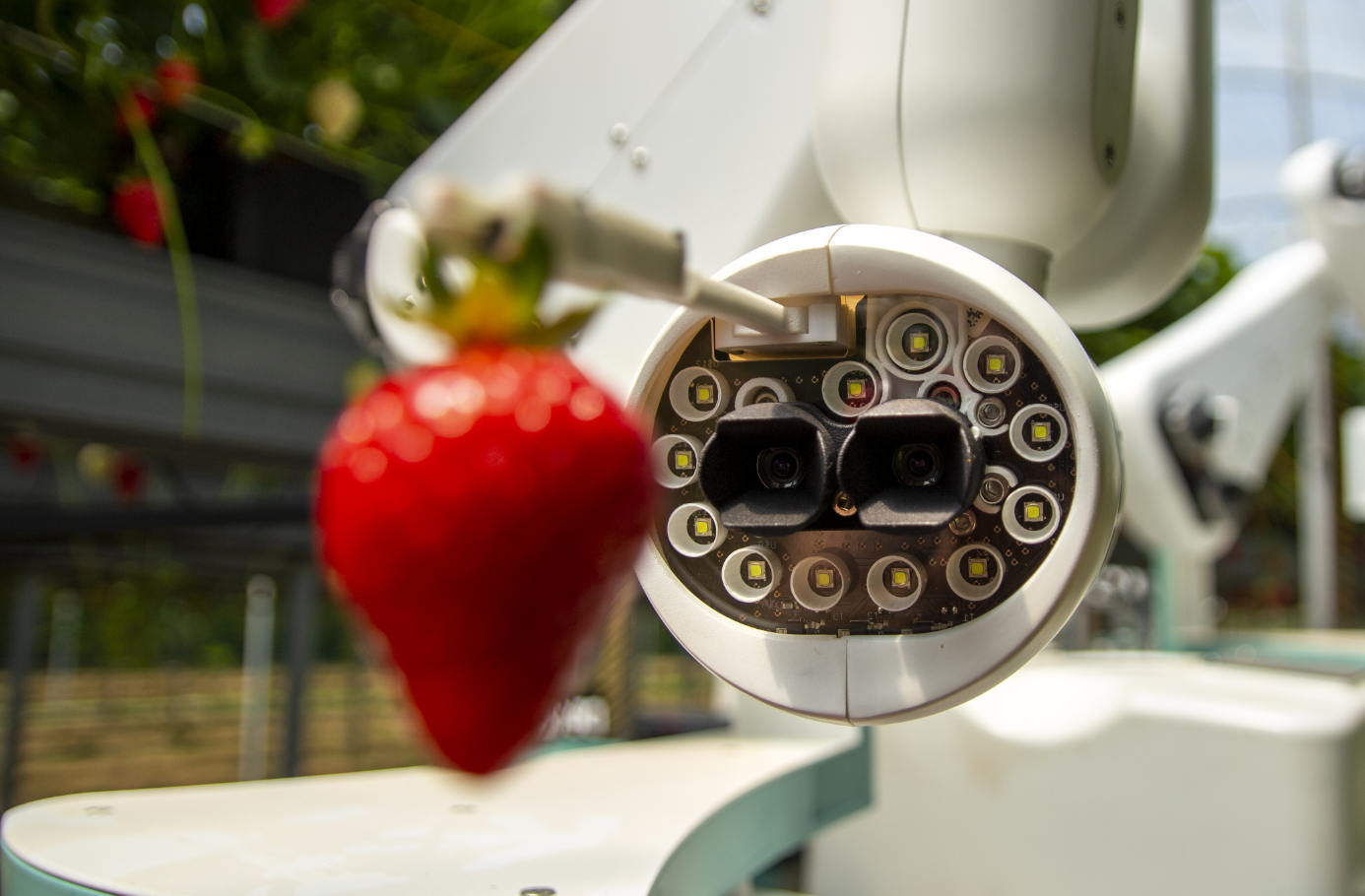

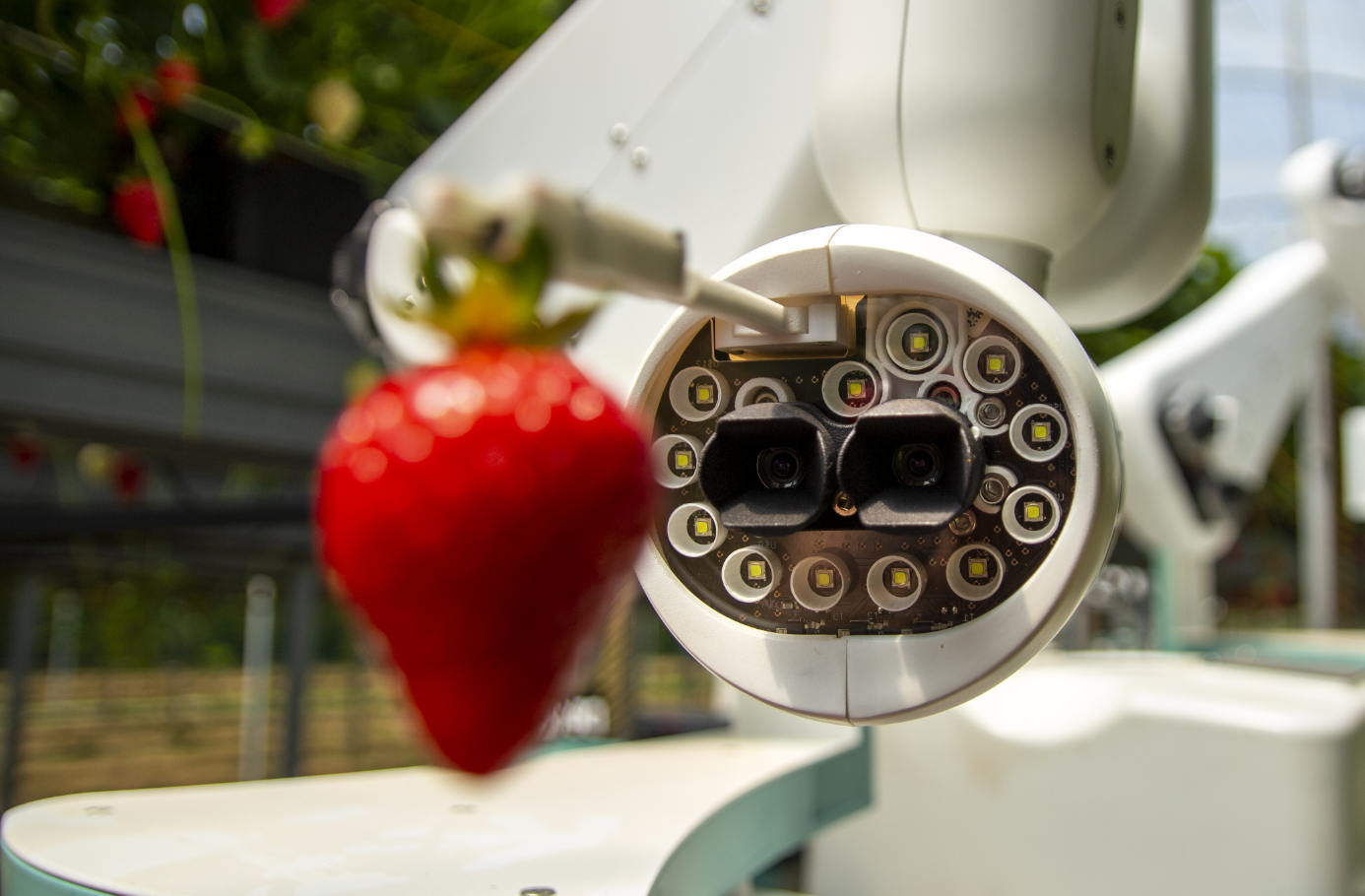

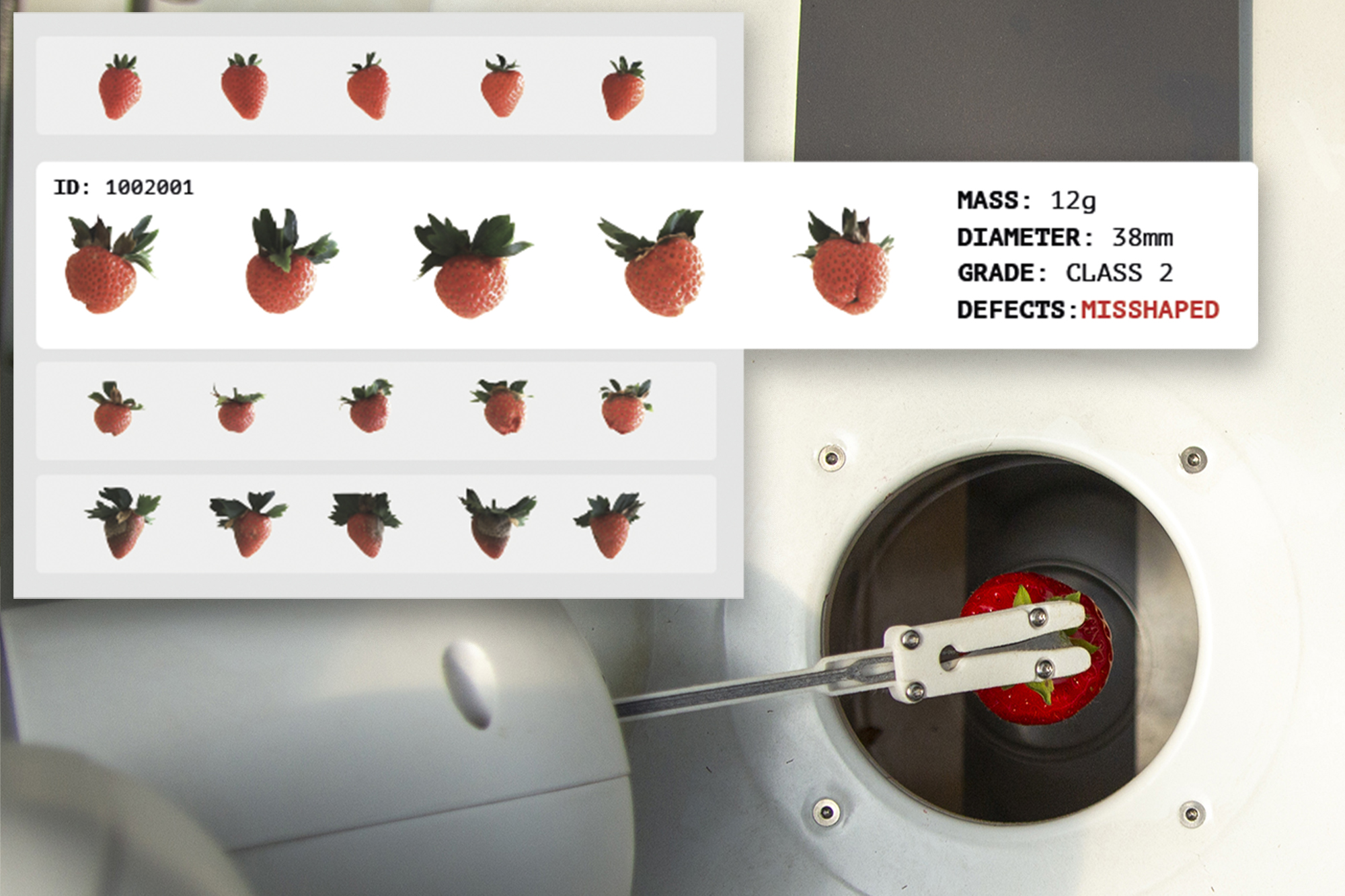

Quality control using on-board inspection

Dogtooth’s patented inspection system images every picked berry to measure weight and diameter. Berries are distributed amongst punnets according to supermarket criteria. Defective berries are rejected.

Web portal allows complete control of your robot fleet

Gain real-time insight into crop conditions including yield and defect rates. Remotely adjust ripeness and grading settings and the trade-offs between wastage, extraction rate and picking speed.

Yield insight from robot data

As they travel down each polytunnel or glasshouse aisle, Dogtooth’s robots count berries at every stage of maturity, providing insight into crop condition and accurate 7-14 day yield forecasts via a cloud-based software UI.

Download tech specs