At the GROWTECH Antalya trade show in November, Dogtooth was delighted to announce the appointment of Fertima as official distributor of our dexterous harvesting robots across Türkiye, Central Asia, and the Middle East. Fertima is a leading supplier of agricultural automation equipment in the region, and they share our commitment to delivering outstanding customer value. This marks Dogtooth’s first distributor partnership, and we look forward to working closely with Fertima to accelerate the adoption of our technology in new regions around the world.

My Internship at Dogtooth by Michelle Sharma

When I first joined Dogtooth Technologies, I was still in the early stages of my career — fresh from university, brimming with curiosity, and eager to apply my skills to something meaningful. I studied Robotics Engineering at the University of Bristol, with a strong interest in robotics, AI, and their applications in solving real-world problems. Agriculture, I’ll admit, wasn’t initially the first sector I imagined working in, but the idea of working with a company that was pushing the boundaries of automation and robotics in the field quickly caught my attention.

Dogtooth stood out to me for two reasons: its innovative approach to agricultural robotics, and the genuine enthusiasm I felt from the team during the interview process. The company wasn’t just building robots — it was building solutions for complex, real-world challenges, like improving efficiency and reducing labour pressures in farming. The chance to work on systems that operate in such dynamic, unpredictable environments was an opportunity I couldn’t pass up.

Over the course of my internship, I had the privilege of working on a wide variety of projects. Some of these were highly technical — developing tools for performance analysis, improving data processing pipelines, and refining algorithms to make our robots more reliable in the field. Other work was more exploratory, such as testing and iterating new features that pushed our systems closer to production readiness. One of my favourite projects was developing a tool that measured performance of the robot’s abilities to pick strawberries at a permutation of approach vectors. It was challenging, often involving digging deep into messy real-world data and teasing out the story hidden inside. But the satisfaction of seeing something you’ve built make life easier for the rest of the team — that’s hard to beat.

In my time here, I’ve learned an incredible amount — not just about robotics and software engineering, but about problem-solving in the face of uncertainty. Technical skills aside, one of the biggest lessons has been learning how to work effectively in a multidisciplinary team. Dogtooth’s engineers, designers, and field teams all bring different perspectives, and the company culture encourages collaboration and open discussion. I’ve also developed soft skills I know will serve me well in the future — from communicating complex technical issues clearly, to taking ownership of my work, to adapting quickly when things don’t go to plan (which, in robotics, they sometimes don’t!).

The work environment here is something special. There’s a real sense of camaraderie; people are not only highly skilled but also genuinely invested in helping each other grow. Mentors have been generous with their time and knowledge, and I’ve always felt trusted to contribute meaningfully. Even on the busiest days, there’s room for humour, problem-solving together over a whiteboard, or celebrating small wins as a team.

Looking back, some of my highlights include seeing our robots successfully navigate tricky conditions in the field, debugging a stubborn problem moments before a test deadline, and those satisfying moments when code you’ve written suddenly “just works” after hours of troubleshooting. Each challenge overcome has been a step forward — not just for the project, but for my own development as an engineer.

Now, as I prepare to leave Dogtooth to pursue a PhD in Defence and Security, I feel incredibly grateful for the experience. My time here has reinforced the value of working on challenging, real-world problems alongside talented people who are passionate about what they do.

For future interns considering Dogtooth, my advice is simple: say yes. You’ll be trusted with real responsibility, you’ll learn faster than you think possible, and you’ll leave with skills and experiences that will shape the rest of your career. It’s a place where curiosity is valued, initiative is rewarded, and where the work you do has a tangible impact.

Thank you, Dogtooth, for the opportunity, the challenges, and the memories. It’s been a privilege to be part of the team, and hopefully our paths shall cross again.

🙂

A Visit from the Cambridge 50th Cub Pack

At Dogtooth, we believe it’s incredibly important to engage and inspire the next generation of engineers and scientists, and our team did exactly that last week at our facility in South Cambridgeshire.

The Cambridge 50th Cub Pack joined us for an action-packed visit filled with hands-on learning and exploration. The Cubs rotated through a series of activity stations in small groups. They got creative with a design challenge aimed at solving real problems in crop surveying, and ventured into the polytunnel for a paired hand–eye coordination game and a mini pick-your-own punnet session. They also had the opportunity to control robotic arms in our “arm farm,” getting a feel for the technology we use in the field. While there weren’t any patents granted, a few Dogtooth branded caps were proudly awarded — and the strawberry ice-cream we made from our surplus strawberries certainly went down well.

There’s real value in giving young people the chance to see our robots up close, and to show that in addition to plastic, copper and steel, the modern world is built from genius, enthusiasm, hard work – and fun!

An Eye-Opening Year as a Software Intern at Dogtooth by Rosia Evans

As I approach the end of my industry year at Dogtooth, I’ve been reflecting on everything I’ve experienced – from technical lessons to unexpected personal growth. I wanted to share my time here, both to document it for myself and to offer insight into what working at Dogtooth is really like.

My Background

I came to Dogtooth looking for an industry year. I wanted a career that combined my love of programming with my love of the outdoors and agricultural robotics seemed like a really good start towards this. Dogtooth felt like exactly what I was looking for. It also provided some interesting ideas: the idea of working towards a new kind of farming with less reliance on mono-crops, less food waste, and although not as strictly related to their work, less reliance on herbicides and pesticides. The idea of automating food production pulled on a political chord in me too, a chance to see what the people working at Dogtooth saw in a future where their product was commonplace.

I also wanted to develop some new skills, especially around electronics and firmware and I wanted to get my foot in the door at a pleasant company so I had somewhere to turn to after university.

What I Learned at Dogtooth

From my first month at Dogtooth I started learning a wild amount. I’d basically been dropped into a new career space and had a lot to take in. Although I joined the software team I was also assigned an electronics and hardware tutor who would meet up with me once a week to help me develop the additional skills I wanted to learn. This was done even though I wasn’t working in that space! This tutoring was amazing and really gave me a lot. Having one-on-one time with someone was so valuable; any question I had was not only answered quickly but in a way that really integrated itself into my understanding well.

I also found that I very quickly learnt a lot about how an entire electronic rig, like our robots, is structured. Learning how a computer can work, manage and run electronic parts really blew my mind! It turns out, our robots have tens of embedded-systems computers inside them, each managing different parts, communicating with a main central computer through a networking system. I’d gone into this assuming there were just chips with massive sets of GPIO pins connecting to all the arms and rails at once. The more I dug into the robots as I worked with them, the more I learnt about the depth of their functioning and the systems Dogtooth has built around them.

Through the job I picked up an insane amount of knowledge about the stuff I was already working on in my life outside of work. To list just a few things off the top of my head: the insane depth of C#’s inner workings and flexibility, Python’s weird little quirks, all the tools and processes for maintaining and running servers and real time data services, and a massive amount just working with a relatively old codebase; seeing what we can do well and badly to ensure the code stays robust and maintainable for years to come.

The Unexpected Lessons

More interestingly, I got a large number of things from my time at Dogtooth that I wasn’t looking for such as interesting views into other worlds and other ways of working. A nice little example of why we should always be pushing ourselves to try new experiences.

An Ego Check

Dogtooth has been a great place for working slightly above my skill level and regularly making mistakes and learning. As an agile company it’s really open to failure and does really well at leaning into a blameless culture. This has been really good for keeping my ego tuned down, regularly reminding me that I don’t know everything, and that I’m surrounded by highly experienced people whose knowledge runs impressively deep. There was a lot of challenging work but my line manager very quickly made sure that I felt I was able to say “I don’t know how to do this, but I’ll give it a go as long as people are willing to help me when I need it”. Developing that kind of knowledge based humility whilst still being willing to undertake tough work feels like a really important skill that I’m glad I developed and I felt like it was definitely at the core of how Dogtooth treats its interns.

Working in a Team with a Range of Opinionated Views

People at Dogtooth are great at their job, and this comes with confidence. They know how to solve a problem and will fight for their view. Coming into these teams and seeing sets of 4-5 people consolidate their mass of widely different points through discussions, compromise and friendly jokes and somehow seeing them all come together in a clean, realistic and reasonable form is incredible. I had moments when I first joined Dogtooth where I’d see this and it would leave me in a really positive mood for the rest of the day. Just being around people as ideas fly and get slowly thinned out through genuine expert discussion is really comforting, especially nowadays when it’s easy to think people with adverse opinions just can’t get on. Dogtooth is really solid evidence against this.

A View into Manufacturing

Dogtooth is a very small company but needs to have a full production team. A nice benefit of this is that this means you have a really wide range of people but everybody still knows everybody. This has given me a chance to get a view into areas of work I would never have otherwise even thought to learn about. This especially applies to manufacturing where the head of the department, has a long and well-established background in the field. Talking to him about this has been profoundly eye-opening. A really interesting view into an industry that’s actually very good at organising humans and solving human problems. Just seeing the whole process a product goes through, from R&D to production to the planning of mass production has been super educational and shown me a whole chunk of the real world I’d never have got to see otherwise.

An Unusual and Sincerely Pleasant Working Environment

A smaller thing, but Dogtooth is just a really lovely environment. I really hoped to get some outdoor manual labour mixed in with my coding whilst working here and I’ve definitely got it. Helping out while a whole team of really lovely people tear-down or rebuild poly-tunnels, weed plants or clear out containers has just been really pleasant. Being able to go and sit outside while working on my laptop on summer days or just having to sit outside whenever a robot needs testing makes Dogtooth a really unique place to work in a really good way; there’s almost a whimsy to it. That whimsy is also added to by having an infinite supply of strawberries to eat during the summer.

I kind of like to think that this is a bit of a window into what computing could be in a world where Dogtooth’s industry is thriving. The programming community definitely needs to be more willing to go outside and Dogtooth sometimes teeters on showing what that could look like. It’s a bit reminiscent of some sort of solarpunk utopian story.

Final Thoughts

That final point definitely ties into my feelings on Dogtooth generally. Working at Dogtooth for a year has really shown me the kind of environments I want to work in. In terms of my future goals and career aspirations, it’s definitely convinced me I want to stay in agri-tech, especially as it continues to grow and carves out its own space. Hopefully it becomes a place with a strong tie to nature, a trust in its workers and an understanding of its own identity. I think Dogtooth is moving in that direction well and I’m definitely hoping to return eventually.

Welcome Aboard Jorge Heraud

Dogtooth is thrilled to announced the appointment of Jorge Heraud as chairman of our board.

Having achieved a significant inflection point in robot productivity, we are now equipping our first customers to adopt dexterous harvesting robots at scale. As we embark on this exciting next phase of our journey, we are hugely fortunate to be able to benefit from Jorge’s experience and wisdom.

To members of the agricultural robotics community, Jorge will need little introduction. He co-founded and served as CEO of Blue River Technology, a company that uses computer vision and AI to detect plants individually and reduce chemical use. After Blue River was acquired by John Deere in 2017, he became their VP of Automation and Autonomy, leading a team of over 600 people. Earlier in his career, he worked at Trimble Navigation International Ltd as Director of Engineering and Business Unit Director for Precision Agriculture. He holds master’s degrees in both engineering and business from Stanford University.

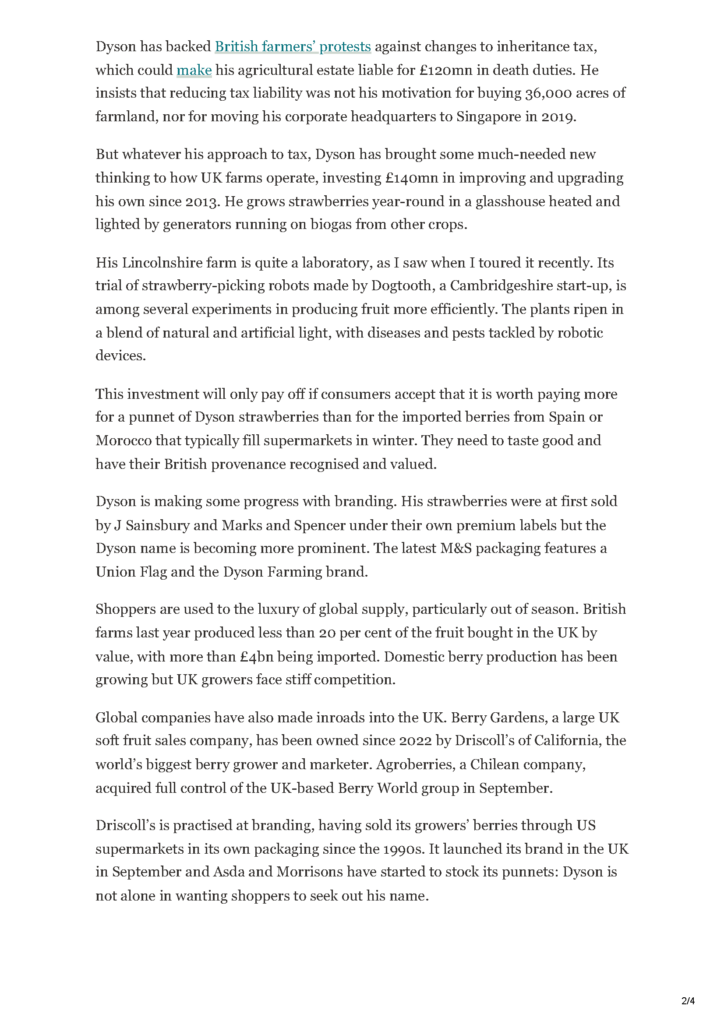

Dogtooth’s Fifth Generation Robot Featured In the Financial Times

Dogtooth’s fifth generation robot was featured in a recent Financial Times article. We are enormously proud to be a part of Dyson Farming ‘s efforts to produce sensational British strawberries this Christmas.

Dogtooth Bronze Winner of the Future of Food Competition 2024

We were thrilled to be one of 16 finalists, selected from over 100 entries across the UK, to participate in the inaugural Future of Food competition.

The competition brought together some of the country’s most innovative food and farming businesses, with each finalist invited to pitch their ideas live to a panel of industry experts and decision-makers at the historic Royal Geographical Society in London.

Future of Food Creator, Barney Mauleverer said, “The mega trends of the future – rising sea levels, shifting populations, threats to our economy, farming and climate, even space tourism are undeniable. But the food industry has a unique opportunity to lead the charge in solving these seismic shifts and crises. It’s incredibly inspiring to see so many young, up and coming innovators forging ahead.

Without the strength of big brands or budgets behind them, they’re making waves, pushing boundaries and showing the incredible talent this industry has to offer. That’s exactly what the Future of Food competition is here to celebrate: their passion, drive and game changing potential.

Dr Duncan Robertson, Founder & CEO of Dogtooth Technologies, leads a pioneering team that has spent eight years developing robots capable of harvesting delicate berry fruits as effectively as human pickers.

Well done to Duncan and the team on winning the Bronze Award!”

Dr Duncan Robertson on stage at the Royal Geographical Society.

Dogtooth Featured in Interesting Engineering

Dogtooth is thrilled to be featured in Interesting Engineering‘s recent documentary alongside other innovators pioneering the use of new kinds of robots in agriculture. With a shortage of skilled harvest labour, the global horticultural industry faces unique challenges. Growers are adopting new technologies to ensure crops are harvested efficiently and Dogtooth’s robots are at the forefront, helping to create a more sustainable and resilient future for farming. Dogtooth is now selling its fifth generation robots to growers around the world. If you’re interested in robotic harvesting on your farm, we’d love to talk to you.

Computer Vision 3D Model Provides A Detailed View Of Plant Geometry

Earlier this year, Dogtooth’s Software CTO Anders Johansson Associate Professor in Engineering Mathematics at Bristol University very much enjoyed working with Bristol Engineering student, Ben Winstanley. Ben used a state-of-the-art computer vision approach to create detailed 3D models of complex plant geometry.

This ability is central to our robot’s ability to pick delicate berry fruits without damage to other parts of the plant. Rather than grasping the body of the fruit, our robots work by gripping and cutting their stalks – an approach that helps to minimize cross contamination and bruising (and that Dogtooth has patented worldwide). For the robot to position its cut/grip end effector with sufficient precision, it must form detailed and accurate 3D models in real time.

Kent’s Growers Given Lesson in Robotic Fruit Picking

Dogtooth recently welcomed some members from Produced in Kent to a demonstration of robotic strawberry picking at a commercial farm in Kent. Members from a wide range of backgrounds enjoyed a presentation from our CEO Duncan Robertson outlining Dogtooth’s journey before seeing our robot fleet picking in the field.

Several generations of robots were on display, picking the everbearer crop highly effectively, as they do throughout the season. The first teams of fifth generation robots to be owned by farmers/growers will be delivered next year, which will be momentous for the soft fruit industry. Get in touch to find out more…

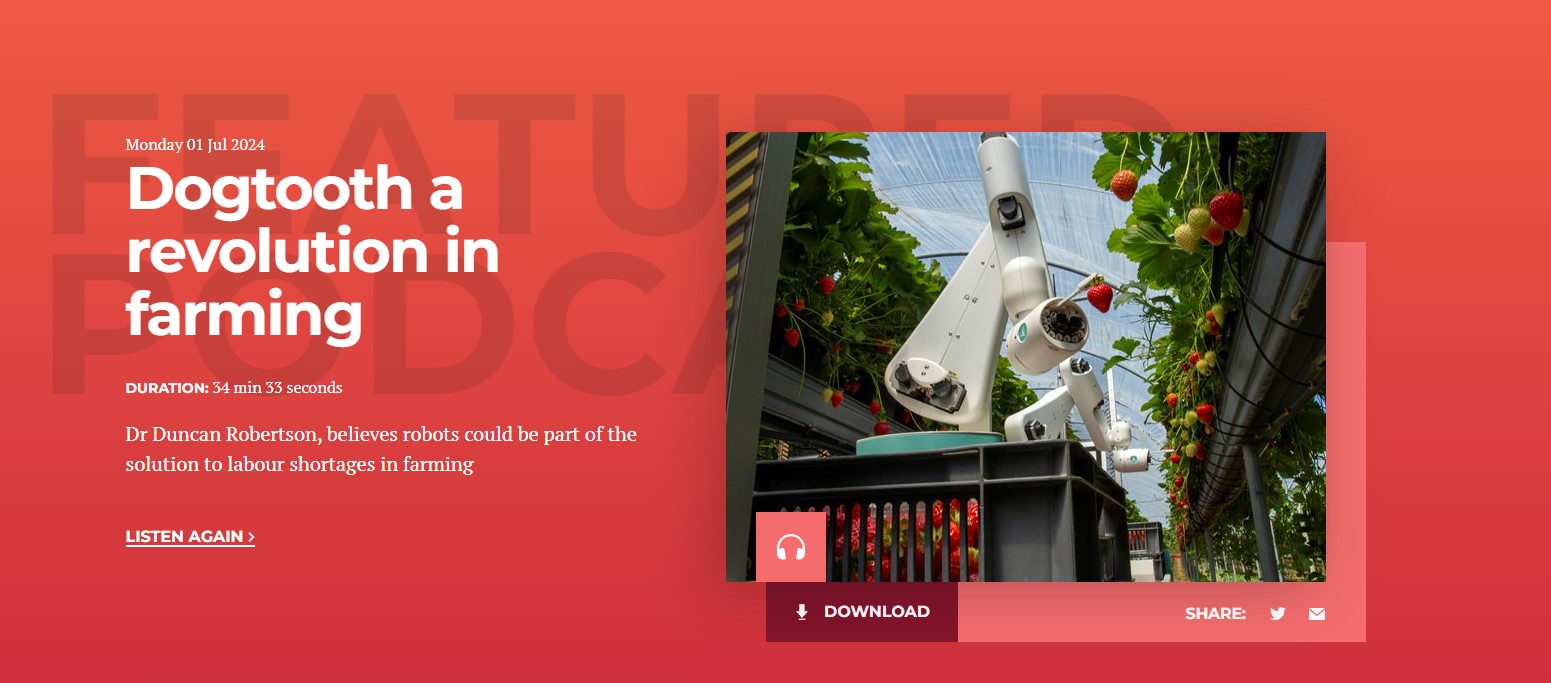

Dogtooth a Revolution in Farming Podcast

Our CEO Duncan Robertson was delighted to participate in this week’s episode of The FoodTalk Show with Susie Warran-Smith CBE DL and Oliver Lloyd – and to discuss Dogtooth’s on-going progress in the area of dextrous harvest automation.

Do listen in via the link below!

https://foodtalk.co.uk/podcasts/dogtooth-a-revolution-in-farming

Dogtooth Teams Up With Fitzbillies

Dogtooth has teamed up with the 100-year-old Cambridge bakery, Fitzbillies, who have crafted a delicious strawberry and cream bun as their summer special, made with strawberries picked by our harvesting robots. Nothing gets past our engineers without being tested. We can confirm that these buns have been thoroughly tested, and they are absolutely delicious! If you are local to Cambridge, these limited-edition buns are available at all Fitzbillies branches.