Dogtooth is thrilled to be featured in Interesting Engineering‘s recent documentary alongside other innovators pioneering the use of new kinds of robots in agriculture. With a shortage of skilled harvest labour, the global horticultural industry faces unique challenges. Growers are adopting new technologies to ensure crops are harvested efficiently and Dogtooth’s robots are at the forefront, helping to create a more sustainable and resilient future for farming. Dogtooth is now selling its fifth generation robots to growers around the world. If you’re interested in robotic harvesting on your farm, we’d love to talk to you.

Rick Stein’s Food Stories on BBC Two

A few of our robots were lucky enough to co-star in Rick Stein’s Food Stories on BBC Two this evening – alongside Sir James Dyson himself. Rick Stein and Sir James have both thought very deeply on the subject of sustainable food production – and by developing state-of-the-art fruit harvesting robots alongside inspiring and innovative customers such as Dyson Farming and Hugh Lowe Farms, Dogtooth is delighted to be doing its part to improve the sustainability and security of UK food production.

If you have access to BBC iPlayer (UK TV license payers only), you can watch the episode here.

Daily Mail Interview with James Dyson

Last week, James Dyson spoke to Sarah Rainey of the Daily Mail ahead of her visit to th Dyson Farming glasshouse in Lincolnshire, where – with the aid of 20 of Dogtooth’s strawberry harvesting robots – the team are working hard to produce British grown strawberries at Christmas.

Read the full article here.

Dogtooth In The News

Dogtooth is making the news! We recently welcomed BBC News to Hugh Lowe Farms to see our strawberry harvesting robots picking fruit in the polytunnels. Their visit was an opportunity to explain how AI and robotic automation are helping to make agriculture become more sustainable.

This clip featured in last week’s episode of “Talking Business” alongside some other remarkable innovations helping to drive sustainability. If you’re in the UK, you can watch the whole episode via BBC iPlayer.

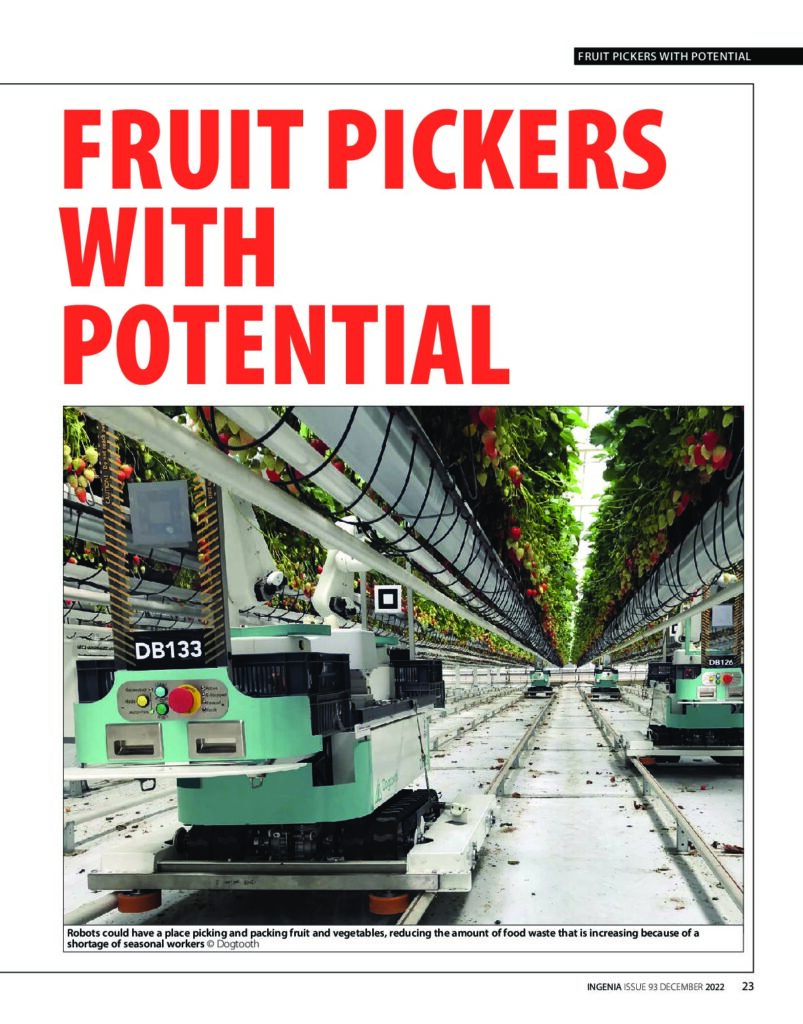

Ingenia Magazine Article

Dogtooth was honoured to feature in last month’s edition of Ingenia Magazine, the official magazine of the Royal Academy of Engineering.

Robotic Harvesting

Our strawberry picking robots work with the table-top growing systems widely used around the world. They are capable of autonomous navigation along crop rows, locating and picking ripe fruit, grading picked berries, and placing them directly into punnets.

Dogtooth is working with prospective customers around the world. As well as alleviating the growing difficulty of recruiting enough skilled picking labour, other benefits provided by robotic picking solutions are of even more interest to customers, e.g.:

• consistent picking performance throughout the working day

• grading and quality control in-situ without repeated handling

• night time picking when temperatures are lower – maximising the shelf life of picked fruit; and

• data gathering for precision crop management to optimise yields, quality and marketing.